Strategies to Prevent Mold Issues During the Commercial Construction Process

7/6/2021 (Permalink)

Blog Summary: SERVPRO of Palo Alto explains how to avoid mold growth during construction.

The commercial damage restoration professionals at SERVPRO of Palo Alto understand the importance of preventing a mold infestation on a construction project. Job delays, health effects, damaged materials, and the risk of future litigation make this issue all too important for the conscientious property owner and project manager. SERVPRO of Palo Alto offers these tips on how to prevent mold growth on a construction job site.

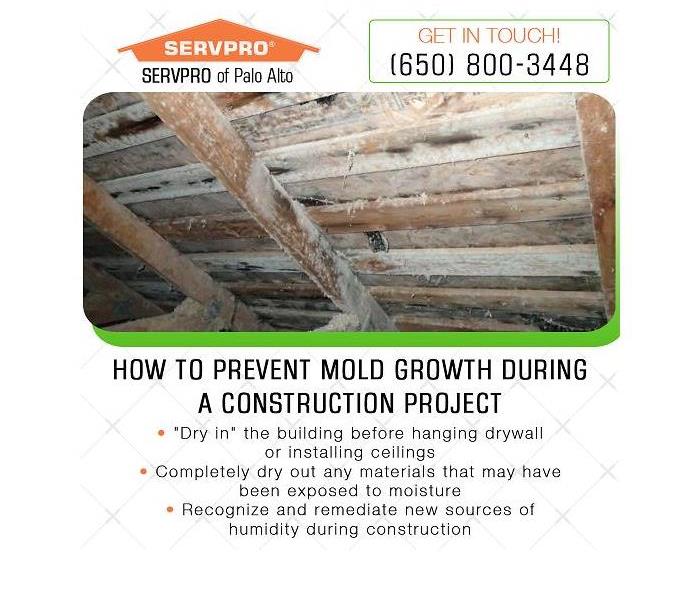

How to prevent mold growth during construction

Mold growth during a construction project is a challenge every property owner will face and must overcome. The following scenario is not unusual, though it is very costly.

Commercial mold infestation scenario

A construction project runs into a major hurdle that brings the project to a screeching halt. A mold infestation is discovered. All the building materials are new, which raises questions about the origin of the mold contamination. An investigation reveals that the construction company failed to complete the dry-in phase before hanging drywall. Inclement weather had soaked the installed drywall. Mold spores feasted on the warm, moist, organic material. Delays and mold abatement drive project costs through the roof. Careful vetting of the construction company goes a long way to preventing problems like this, but steps can be taken during the inspection process to avoid mold issues.

How does mold grow?

Mold spores are present everywhere in the environment. An infestation or high concentration of spores is possible when food, wetness, and warmth are available. On a construction project, food for mold is everywhere. Ceiling tiles, lumber, and drywall are favorite foods for mold.

In the initial stages of a construction project, organic matter is limited, especially if the flooring is concrete and the framing is metal. Lumber and subflooring are relatively hard, and they do not facilitate mold growth unless exposed to moisture for an extended period. On the other hand, the soft, organic matter in ceiling tiles and drywall promotes mold growth and can harbor an infestation in as little as two or three days after exposure to moisture.

How to prevent mold growth during a construction project

What is the most effective means to prevent mold growth during a construction project? The answer is simple. Keep vulnerable materials dry. The following three-pronged strategy works every time.

#1. “Dry in” the building before hanging drywall or installing ceilings.

The process of sealing the building envelope prevents moisture from penetrating the interior. The proper installation of exterior siding, windows, seals around windows and doors, and, most importantly, a water-tight roof are crucial in this “dry-in” phase.

#2. Completely dry out any materials that may have been exposed to moisture.

The building materials may have already been installed, or they may be awaiting installation. As long as the materials are laden with moisture, the risk of mold growth is high. Wooden framing and subfloors can absorb moisture. If installed before drying out, the wood can release moisture into the indoor environment of the building. The drywall will absorb the moisture like a thirsty sponge, increasing the likelihood of a mold infestation.

#3. Recognize and remediate new sources of humidity during construction.

Even though a structure’s building envelope is water-tight, mold growth can occur if moisture is introduced into the building. Renovation of an existing structure that requires the removal of asbestos or drywall involves a process that uses water to control dust. The mitigation of this moisture may necessitate the deployment of dehumidifiers during the construction process.

Mold identification: What to look for and when

To prevent expensive mold issues, check for moisture during walk-through inspections with the project manager or general contractor.

- Before installing drywall

The building envelope should be tightly sealed. The roof, windows, doors, and exterior siding should be installed, and all gaps should be sealed. Ensure that any lumber or other wood products that might have been exposed to water or moisture have been thoroughly dried out.

- During and after demolition

Renovation projects that involve the removal of asbestos or drywall require large amounts of water. Verify that proper dehumidification has been exercised. Excess water should be removed prior to the installation of new materials. Relative humidity should be sustained at sixty percent.

- Before a pause or shutdown

Sometimes a project must be paused temporarily or shut down indefinitely. Make sure that the site is dried and sealed appropriately to prevent mold growth during the lull. The installation of dehumidification equipment may be necessary. The extra expense is negligible when compared to the cost of mold mitigation and project delays.

How costly is a mold issue on a construction project? Consider the following expense items:

- slowed or paused project progress

- delayed completion dates and any penalties arising from these delays

- replacement of affected or damaged materials

- remediation expenses

- expenses for an abatement contractor (which is sometimes legally required)

Mold prevention on the construction job site involves proper planning, detailed inspections, and immediate action when conditions conducive to mold growth are discovered. When a mold infestation is identified, stop mold in its tracks. Enlist the services of a professional mold mitigation and remediation company to stop the mold infestation, clean up the job site, and mitigate any moisture issues with water removal, water extraction, and applied structural drying techniques. SERVPRO of Palo Alto can also deploy industrial-grade dehumidifiers to achieve the desired humidity level and maintain that level throughout the project. The team of SERVPRO professionals utilizes advanced technology to detect moisture and monitor humidity on a commercial job site. The proactive property owner can save hundreds of thousands of dollars in unnecessary expenses by taking care of mold before it becomes a problem.

Available 24 hours a day and 365 days a year, SERVPRO of Palo Alto helps regain control of a commercial property damage incident and begin the damage restoration process quickly. A prompt response, rapid remediation, and minimal or no disruption of business or construction operations enable the project to move forward.

For more details about commercial damage restoration in Sunnyvale, CA, and the surrounding area, email SERVPRO of Palo Alto at office@SERVPROpaloalto.com or call (650) 800-3448.

24/7 Emergency Service

24/7 Emergency Service